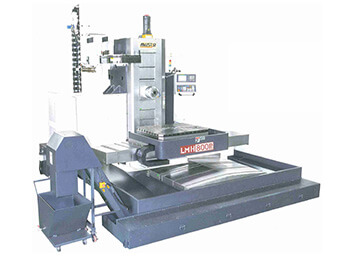

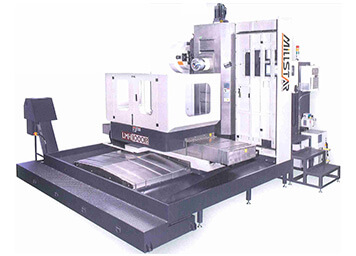

Horizontal Machining Center

What Is Horizontal Machining Center (HMC)?

The machining center is a CNC machine with multi-purpose functions, while the horizontal machining center ( HMC ) is a machining center whose main axis is parallel to the workbench and the floor, has better chip removal ability, horizontal direction design makes the chips fall automatically, and there is no need to manually remove the chips on the workbench. The horizontal machining centre is capable of accommodating two pallet changers, allowing unattended production work and reducing part cycle times.

1. Millstar HMC machine lets multiple operations can be done in a single setup and is best suited for large-scale and fast productions.

2. Provide high rigid designs horizontal machining centre series from 630mm table size to 1000mm table size, its durability allows for less wear and tear on the machine, further reducing costs and providing more reliability. Besides we have a single table model that provides a bigger table size and loading capacity for heavy-duty industry to provide unlimited possibilities for the shape of the parts you process.

3. JMH series horizontal machining center is equipped with an automatic pallet changer (APC), when the components are loaded onto the pallet while the machine is cutting, and then automatically and quickly transferred after the cutting cycle is completed to machining centers, which can effectively save the downtime wasted by the operator manually loading and unloading on the machine table, increasing spindle utilization and reducing operator workload.

4. Millstar horizontal machining centers are widely used in various industries due to our higher processing probability and capability, such as the automotive industry, power generation, hardware, and oil&gas industries

As a professional CNC machining center manufacturer, we adhere to the core value of innovation and exquisite design, continuously enhance product modularization technology and develop various systems to enhance product automation applications, in order to improve peripheral performance, so that the designed machining center can achieve improvement The purpose of productivity and precision, to provide customers with the most cost-effective solutions!

For more detail about our horizontal machining centre or horizontal milling machine, just feel free to contact us!

Q1: How to Horizontal Machining Center Work?

Horizontal machining centers usually have a vertical axis that allows you to adjust the height of the spindle, and two horizontal axes that can move the table vertically and laterally. After the workpiece is clamped on the machine table, it is controlled by the CNC system and automatically selects different tools and can change the spindle speed of the machine tool and drives the X, Y, and Z axes cut(process) the workpiece from various angles, which is suitable for projects that require sideways work or projects that require multilateral cutting.In summary, HMC is worked by advanced technology and precision control to achieve high-speed, high-precision machining.

Q2: How to choose the size of horizontal machining centers?

There are different options depending on the part shape, size, complexity, material, etc. you want to manufacture.

Q3: What different materials can horizontal machining centers?

Which materials can be machined by HMC depends on factors such as spindle speed, tool options and cutting parameters. In general, HMC can process a wide range, such as metal processing (steel, aluminum, copper, brass, titanium and nickel alloys), composite material processing for the aerospace and automotive industries and ceramic materials for the medical and dental industries, etc.

Q4: Do you provide after-sales services?

Yes, we provide comprehensive after-sales repair services, including troubleshooting, parts replacement, and maintenance. Customers can contact our service team at any time for support.|

Horizontal Machining Center (HMC Machine) |

||

|---|---|---|

|

Advantages |

|

|

|

Disadvantages |

|

|

|

Applications |

|

|