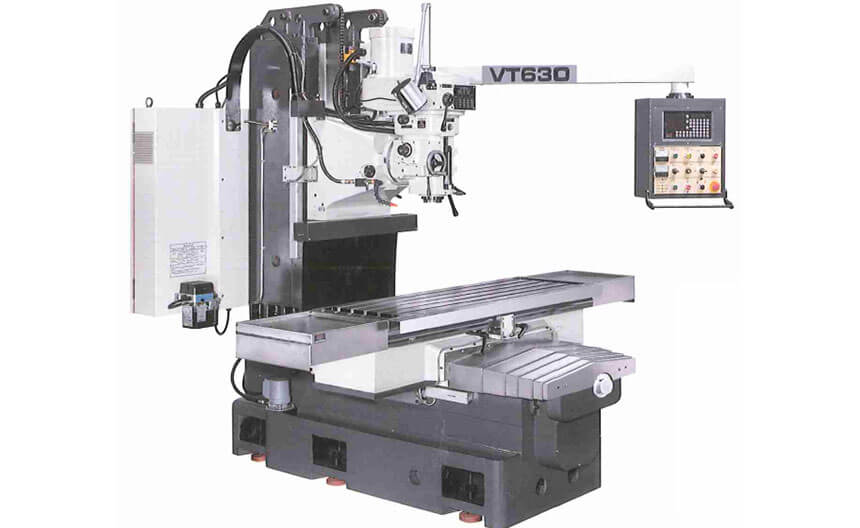

VT series (Vertical Turret Head)Conventional Milling Machine

VT630 Vertical Spindle Milling Machine

- Integrated automatic lubricating system and cooling system

- The X, Y axis slideways coated with low-friction property material TURCITE-B

- Standard electrical and electronic components are adopted.

- Electrical and electronic circuits are properly concealed.

VT630 vertical spindle milling machine is extremely versatile and can perform a variety of tasks. The vertical orientation makes it easier to insert and remove cutting tools. The controls are integrated on a panel, enhancing simple and easy operation thus avoiding fatigue and increasing working efficiency. The VT630 vertical spindle milling machine consolidated rigid cast-iron design treated annealing process and the slide surface is hardened, the rigid structure ensures stable machine performance, providing high precision and reliable operation.

This vertical spindle milling machine has a low workbench height that facilitates workpiece handling. Each travel axis is equipped with limit switches to ensure safety.

Millstar VT630 vertical spindle milling machine is cheaper and more compact than horizontal spindle mills, suitable for smaller shops and budgets.