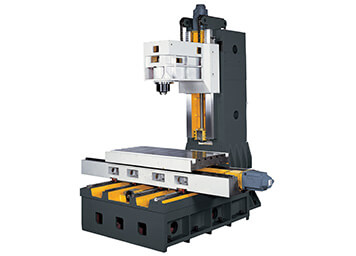

Vertical Machining Center

What is Vertical Machining

A vertical machining center also known as a VMC machine is a high-precision CNC machine tool, vertical machining center working principle of the vertical machining center is to fix the workpiece on the worktable, and the tool is pressed down from above to cut. It is suitable for high-precision machining of planes, contours and holes.

VMC machine provides cutting, milling, drilling and other processing operations that can be used for processing metals, plastics and other materials. Vertical machining centers have characteristics of high precision, high efficiency and flexibility that can help enterprises improve production efficiency, reduce production costs and improve product quality, so it is widely used in various fields.

Millstar vertical machining center manufacturer provides VMC machines made of adapts linear guideway & box guideway structure movement, VMC travel from 660mm to 2000mm which satisfies all kinds of processing size requirements. Our vertical machining centers have a higher processing probability and capability widely used in various industries, such as hardware, oil and gas industries, power generation, and automotive industries. For more details about our vertical machining center, send us an inquiry now!

BMV/BV series

BMV series (4 Box Way)Vertical Machining Center

Heavy Duty BMV series (6 Box Way)Vertical Machining Center

High Speed Type Vertical Machining Center

-

(BT40) X1500 / Y825 / Z750

(BT50) X1500 / Y850 / Z750 -

(BT40) X1600 / Y825 / Z750

(BT50) X1600 / Y850 / Z750 -

(BT40) X1700 / Y825 / Z750

(BT50) X1700 / Y850 / Z750 -

(BT40) X1800 / Y825 / Z750

(BT50) X1800 / Y850 / Z750 -

(BT40) X2000 / Y825 / Z750

(BT50) X2000 / Y850 / Z750

LMV/LV series

High Speed LMV series (4 Linear Guide Way)Vertical Machining Center

-

(BT40) X1200 / Y620 / Z650

(BT50) X1200 / Y620 / Z650

High Speed Type Vertical Machining Center

APC series (2 Linear Guide Way)Vertical Machining Center