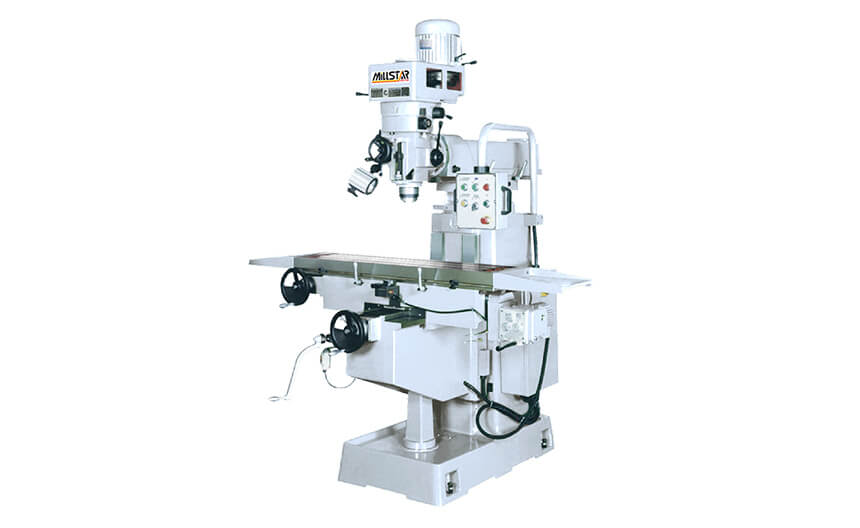

New Knee Type Milling Machine

JY-860

(Auto)X860 / Y400 / Z470

(Manual)X860 / Y400 / Z470

(Manual)X860 / Y400 / Z470

- The main casting part is made of meehanite casting.

- The spindle is one piece machined from SCM440 alloysteel, thermal refining, high-frequency and precision polishing.

- Milling head type:

- Maximum spindle speed up to 5560rpm/50HZ

- Used type B belt drive.

- Hardened and ground X,Y,Z axes slideway.

- Turcite-B coated on X Y ways.

- Square way design on Y and column slideway.

- X/Y axis are using precision ball screw.

-Steps (S) Inverter (C)

| 10 Steps | |

|---|---|

| 60HZ | 70-125-190-285-420-600-1025-1530-2200-3350(RPM) |

| 50HZ | 58-110-165-240-360-500-870-1290-1900-2780 (RPM) |

| 20 Steps | ||

|---|---|---|

| 50HZ | 2P | 116-220-330-480-720-1000-1740-2580-3800-5560(RPM) |

| 4P | 58-110-165-240-360-500-870-1290-1900-2780 (RPM) | |

-Inverter type used YASKAWA VFD.